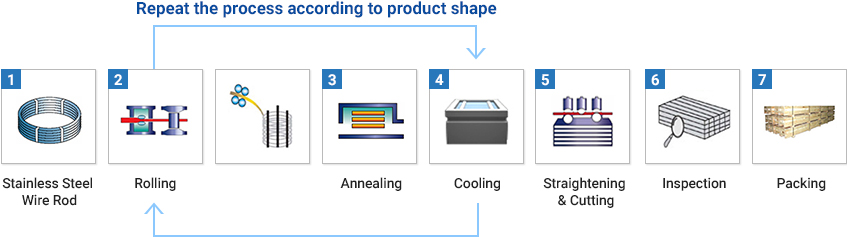

Production Process

Step 1Stainless Steel Wire Rod

BELLUS use stainless steel wire rod as raw material.

Through our technology, round shape of wire rod is changed into various shaped straight bars.

Step 2Cold Rolling

The Cold Rolling is a production process that the rotators compress a wire rod at room temperature. Cold rolling technique requires a high degree of precision to create a various shaped bar.(ex. square, triangle, rectangle, flat, profile).

Step 3Annealing without oxidation

BELLUS use electricity to raise temperature with indirect annealing treatment. (Annealing Temperature : 1050 ℃)

Step 4Cooling (Air cooled System)

The annealed wire is not exposed to water directly. The wire enters into stainless pipe and the surface of stainless steel pipe is cooled by cooling water.

Step 5Straightening & Cutting

The cooled wire is straightened and cut into a stainless steel bar. The stainless steel wire rod is created to stainless steel bar.

Step 6 & 7 Inspection & Packing

Stainless steel bars are bundled in wooden boxes, after inspection.